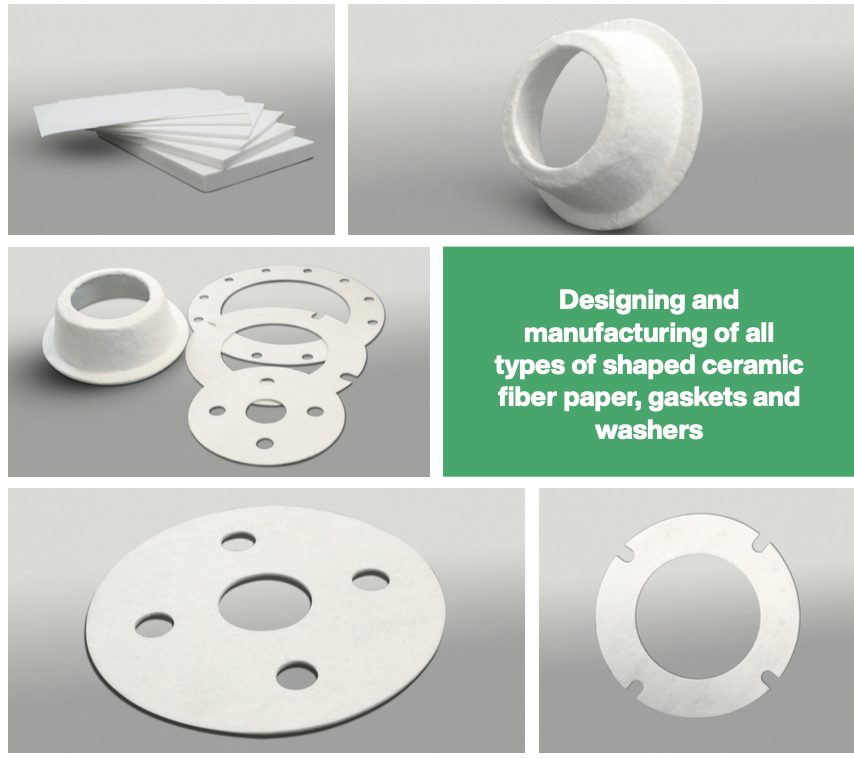

Ceramic fiber paper is a type of ceramic- based insulator that can be produced from various ceramic fibers including HA and HZ, and it shows excellent resistance to high temperature and harsh mechanical and chemical environments. These have made ceramic fiber paper a suitable choice of insulation for environments where features such as resistance to high temperature, thermal shock and corrosion are required. Flexibility, consistent thickness and high tensile strength are among other unique features of this product. Compared to ceramic fiber blanket, even though paper is thinner, it has a lower heat transfer rate.

Ceramic fiber paper is a white insulator that can stand high temperatures up to 1430 C°. One of the main characteristics of ceramic fiber paper is that since it does not contain asbestos, it is not harmful to the environment or humans, making it a great substitute for asbestos-based products.

In addition to the features mentioned above, resistance to a wide range of corrosive chemicals and oxidants, ease of installation, resistance to wild temperature fluctuations and the ability to be used as a noise insulator have attracted various industries to ceramic fiber paper.

Today many industries benefit from all the advantages that ceramic fiber paper has to offer. Some of the main applications in industries are:

Sealing gasket in petrochemical industries

Heat insulation of equipment used in fuel stations and oil storage tanks

Pipe insulation in environments with high temperature or casting industries

Heat insulation of equipment in power plants

Heat insulation of catalytic converter exhausts in the automotive industry

Heat insulation of furnaces and industrial vessels

Heat insulation of ovens and boilers

Safety clothing and equipment including lining in firefighters’ uniforms and refractory bags Heat insulation to minimize heat loss in nozzles

Lining for insulation of molds

Electrical insulation in the electrical industry

A substitute for asbestos products

Sound and heat insulation in the construction industry

Ceramic Fiber Paper Features

Consistency, light weight, flexibility, white color

High thermal resistance (1260, 1360, 1400, 1430 degrees Celsius)

High durability

Formability and easy installation

Resistance to thermal shock

Proper mechanical resistance and high tensile strength

Resistance to various corrosives

Ability to be used as electrical insulator due to its proper dielectric properties Proper for sound insulation due to its sound absorption properties Environmentally friendly